products introducion

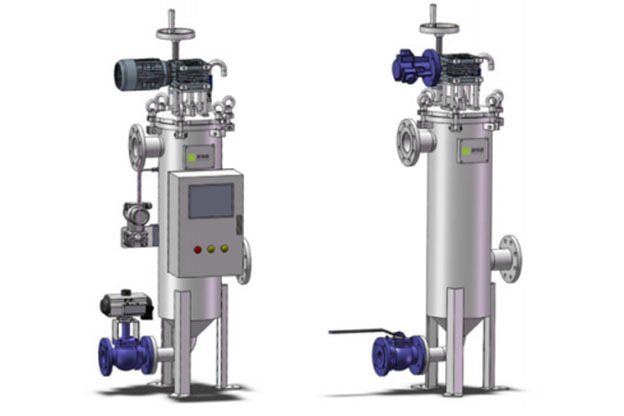

Self-Cleaning Scraper Filter

The external self-cleaning Scraper filter utilizes a rotary scraper for automatic removal of impurities and debris, eliminating the need for manual cleaning. By consistently removing impurities, it ensures continuous operation, saving manpower, reducing production costs, and achieving industrial waste reduction, thereby lowering environmental treatment expenses.

self-cleaning scraper filter's Specifications:

Theoretical Flow Rate (100µm): 10-82m³/h. Actual flow rate is influenced by liquid viscosity, filtration precision, and turbidity.

Operating Temperature: 160℃. Requires a high-temperature-resistant seal to achieve.

Operating Pressure: 1.0MPa. This is the standard operating pressure; customization is available for higher pressure requirements.

The external scraper filter is equipped with high-quality V-SLOT gap-type precision metal filter elements:

Filtration precision range: 50-500 microns.

Accurate gap width with a deviation less than 5 microns.

Main body made of 316L material with excellent corrosion resistance.

V-shaped gap design prevents impurities from clogging, maintaining stable flow over the long term.

Smooth outer and inner surfaces.

High-strength structure maintains gap integrity even under increasing pressure differentials.

Withstands high-intensity pressure shocks in both directions.

scraper self-cleaning filter's Application Range:

Suitable for filtering liquids such as wax, shampoo, rubber, citric acid, grain syrup, high-temperature oil, kerosene, silicone resin solution, ethanol, fermentation liquid, juice, cellulose, resin, soap, chocolate, chemical agents, coolant, cosmetics, polymers, coatings, candy, pigments, catalysts, penicillin, water treatment, steroids, dairy products, diesel, pills, lubricants, vitamins, sterols, edible oil, and more.

self-cleaning scraper filter's Advantages:

Fully automatic operation with 24-hour continuous online filtration, eliminating the need for labor-intensive filter element replacement and cleaning.

Eliminates disposable filter consumables, saving consumable and environmental processing costs.

Uses metal blade scrapers for outstanding debris removal, significantly enhancing impurity removal capabilities while avoiding impurity compression and breakage.

High-quality V-SLOT filter elements with precise gaps, smooth surfaces, easy cleaning, high strength, and long lifespan.

Minimal pressure loss during filtration, maintaining stable flow and saving pipeline energy consumption for continuous and stable processes.

Sealed filtration prevents leakage of hazardous materials, promoting safety in production.

High impurity concentration in discharged waste liquid allows for recovery, avoiding the loss of high-value materials.

Multiple module combinations and automation modes are available to meet various filtering application requirements.

Equipped with internationally renowned brand gear motors for high reliability and long service life.

Shanghai Sffiltech Co.,ltd is a professional manufacturer of external self-cleaning scraper filters, offering a diverse range of models and scientifically validated materials to effectively meet filtration needs. Additionally, our filters are competitively priced, ensuring both quality and affordability. We also provide various customization options to enhance the filtration process and meet specific requirements. Optional features include:

Insulation jacket for conducting thermal oil (2kg/cm²) or hot water (4kg/cm²), maintaining temperature and conveying performance.

Explosion-proof design for safe filtration of flammable and explosive liquids.

Food-grade surface polishing for easier cleaning.

Top cover with auxiliary lifting arm design for easy maintenance.

Modular serial combination to meet higher flow rate filtration requirements.

Mobile filtering carts for flexible filtration at multiple locations, saving investment costs.

0users like this.